All You Should Know About litho printing

All You Should Know About litho printing

Blog Article

A Comprehensive Guide to Understanding Litho Printing Methods

The globe of litho printing, a strategy stemming from the late 18th century, is a remarkable mix of history, advancement, art and science. This detailed guide will certainly unravel the intricacies of this printing method, from the make-up of litho inks to the difficulties encountered in contemporary applications. As we venture right into the complexities of lithography, the relevance of automation and sustainability in guaranteeing its future significance becomes progressively clear. Stick with us as we trip right into the captivating world of litho printing.

The Historical Development of Litho Printing

The historic trajectory of litho printing, an essential advancement in the realm of communication, is a captivating tale of human resourcefulness. The procedure advanced with the arrival of the rotating press, which considerably boosted efficiency. Each stage of litho printing's development showcases mankind's unrelenting quest of effectiveness and quality in aesthetic interaction.

Decoding the Scientific Research Behind Litho Printing Inks

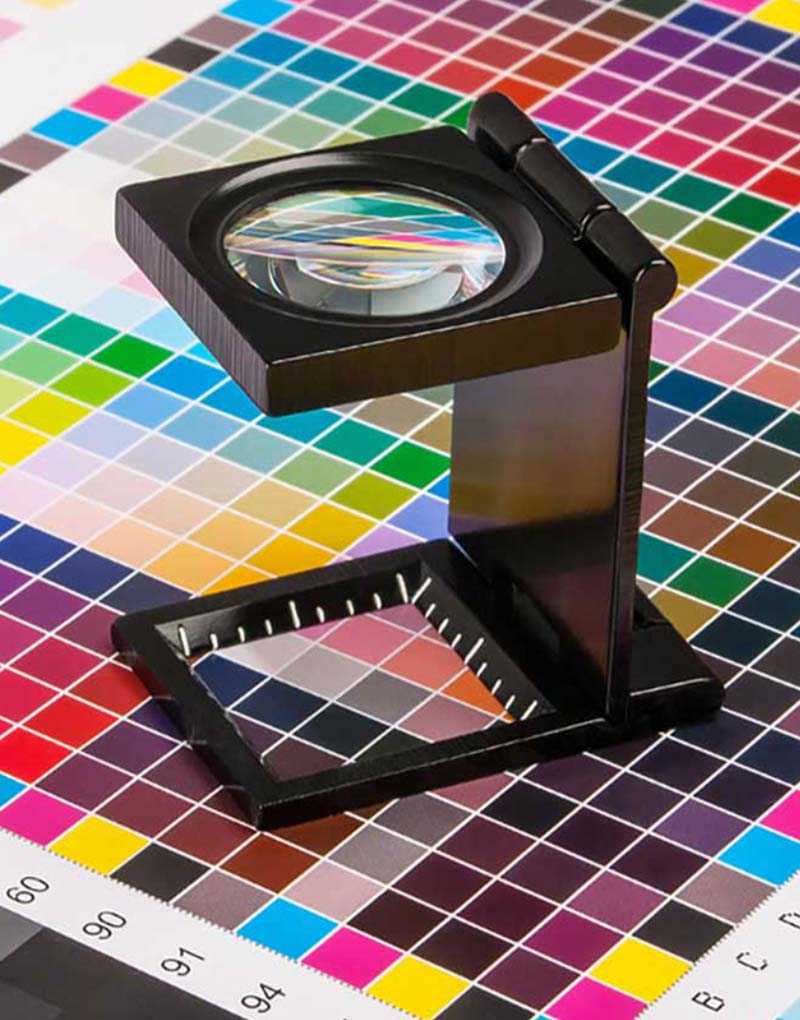

Moving on in the expedition of litho printing strategies, the focus now changes to the scientific research behind litho printing inks. The composition of these inks, their drying procedure, and color mixing strategies create the foundation of this complicated art kind. Recognizing these elements is crucial to grasping the craft and achieving the wanted print outcomes.

Structure of Litho Inks

In lithographic printing, the essential duty of litho inks can not be overstated. Pigments, the color-providing aspects, are carefully ground fragments put on hold in the automobile, a fluid that brings the pigment onto the printing surface area. Each element plays an important part in the last print's high quality, making the precise formula of litho inks a detailed scientific research.

Ink Drying Refine

From the composition of litho inks, interest turns to the fascinating procedure of ink drying out. The drying process is essential, as it impacts the last print's top quality and longevity. 2 key approaches are made use of in litho printing: oxidative drying out and absorption. Oxidative drying entails the ink reacting with oxygen in the air to form a tough, dry film. This approach offers a sturdy surface, but can be slower contrasted to absorption. Absorption, on the various other hand, includes the ink leaking right into the paper fibers, which is a faster procedure however can result in much less lively shades. The selection between these techniques depends on factors such as print speed requirements, the paper type made use of, and the desired coating.

Shade Combining Strategies

While the drying process plays a key function in litho printing, the scientific research of color mixing techniques holds equal relevance. The science behind litho printing inks likewise takes into account the transparency of the ink, which affects exactly how colors overlay and mix.

The Art and Design Aspects in Litho Printing

Litho printing breathes life into art and style with its special aspects. Litho printing accommodates a variety of shades, allowing artists to develop dynamic and lively prints. This combination of accuracy and versatility makes litho printing a recommended choice for several artists and developers.

Modern Applications of Litho Printing Strategies

Litho printing techniques have located considerable use in the contemporary commercial market. Its influence and relevance proceed to expand with the introduction of brand-new advancements and technologies in the area. This section will certainly explore these contemporary applications and the transformative function they play in the printing sector.

Business Litho Printing Utilizes

In today's electronic age, one may ask yourself about the significance of conventional printing approaches. Litho printing continues to be a vital part of the commercial market. High-volume printing tasks, such as the production of publications, papers, and product packaging, rely upon litho printing for its capability to provide superior image top quality and price effectiveness. The process, which includes moving a tattooed picture from a plate onto a rubber covering and afterwards to the printing surface area, supplies unequaled consistency. This makes it ideal for jobs requiring a large print run. Litho printing also gives a wide shade range, above that of electronic printing. This makes it the go-to selection for projects that require vivid, high-quality color recreation.

Developments in Litho Printing

Pushing the boundaries of standard methods, modern-day advancements have actually fueled a host of innovations in litho printing. These innovations have not just enhanced the top quality and efficiency of litho prints yet additionally broadened its application scope. One noticeable development is digital litho printing, which incorporates the virtues of digital technology with litho's top notch result. This hybrid design supplies faster configuration times, lowered waste, and makes it possible for on-demand printing. An additional notable development is the intro of eco-friendly inks. These inks, made from vegetable or soy-based options, have considerably reduced the sector's ecological influence. litho printing. In addition, the advancement of innovative plate modern technology has streamlined the printing process, leading to sharper images and improved shade fidelity. These developments emphasize the long-lasting significance of litho printing in the modern-day world.

Discovering the Process of Litho Printing: Action by Action

Obstacles and Solutions in Contemporary Litho Printing

In spite of the accuracy and tradition that litho printing proudly promotes, it is Visit Website not without its set of modern obstacles. Digital litho printing enables for affordable brief runs and simple customization, attending to the issue of variable data. Thus, while there are challenges, the litho printing industry is proactively adjusting to meet them head-on, ensuring its significance in the future.

Conclusion

In final thought, litho printing, with its rich background and scientific intricacies, holds a significant location in the print market. The future of litho printing hinges on its capacity to adjust to these changing needs, verifying its enduring value in a developing market.

Report this page